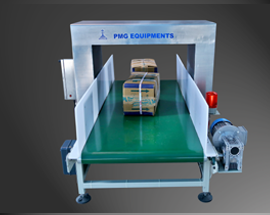

Food metal detectors are an essential piece of equipment used in the food industry to ensure the safety and quality of food products. They are designed to detect the presence of any metal contaminants in food items, such as metal fragments or foreign objects that may have accidentally ended up in the food during the production process. This essay will discuss the importance of food metal detectors, their working principle, and the benefits they provide to the food industry.

The food industry is one of the largest and most important industries in the world. With the growing demand for food products, manufacturers are under immense pressure to produce large quantities of food in a short period of time. In such a fast-paced environment, it is inevitable that mistakes can happen, and food items can be contaminated with foreign objects. This is where food metal detectors come into play. They are a crucial part of the quality control process, ensuring that all food products are safe for consumption.

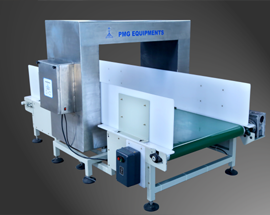

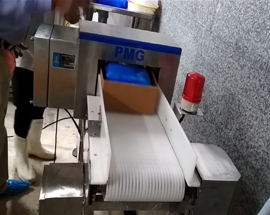

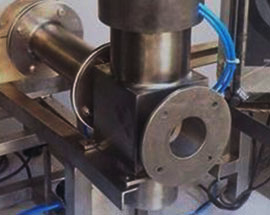

Food metal detectors work on the principle of electromagnetic induction. They consist of a transmitter coil and a receiver coil, which are placed in close proximity to each other. When a metal object passes through the detector, it disrupts the electromagnetic field between the two coils, triggering an alarm. This allows for the immediate removal of the contaminated food item, preventing it from reaching the consumer.

The use of food metal detectors has become mandatory in many countries, as food safety regulations have become more stringent. This is a positive step towards ensuring the safety of food products and protecting consumer health. With the rise in food allergies and intolerances, it has become even more crucial to eliminate any potential hazards, including metal contaminants, from the food supply chain.

One of the main benefits of using food metal detectors is that they can detect even the smallest metal particles, making them highly sensitive. This is essential as even a tiny metal fragment can cause serious harm if consumed. In addition, food metal detectors are also equipped with advanced technology, such as multi-frequency detection, to ensure that all types of metal are detected, regardless of their size, shape, or location within the food product.

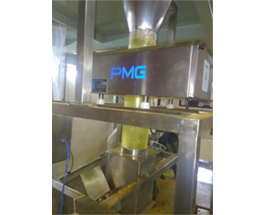

Moreover, food metal detectors are also highly versatile and can be used in various stages of food production, from the raw material stage to the final packaging stage. This allows for effective detection and removal of metal contaminants at every step of the production process, ensuring the overall safety and quality of the final food product.

Aside from ensuring food safety, food metal detectors also offer financial benefits to food manufacturers. By detecting and removing metal contaminants, they prevent costly product recalls, which can damage a company’s reputation and lead to financial losses. In addition, they also help in reducing waste and improving overall production efficiency, resulting in cost savings for the manufacturer.

In conclusion, food metal detectors are an essential tool in the food industry to ensure the safety and quality of food products. With their sensitive detection capabilities, advanced technology, and versatility, they play a crucial role in preventing metal contaminants from reaching consumers. As the demand for food products continues to rise, the use of food metal detectors will become even more vital in maintaining the integrity of the food supply chain. Therefore, it is imperative for all food manufacturers to invest in high-quality food metal detectors to uphold food safety standards and protect consumer health.